Welcome!

Welcome to my personal webpage. The purpose of this page is to document some of my academic and industrial experiences, publications and provide a means to communicate with you. I enjoy working with other researchers and scientist, in the field of Smart Materials, Structural Health Monitoring of Aerospace Structures and Computational Modelling. I truly believe this to be fantastic fields of research and every day I feel blessed to be part of it.

Thank you for your visit,

Marcias Martinez

My Education

Ph.D. (Mechanical Engineering)

January 2000 - October 2006

Carleton University, Ottawa, Canada

Research: Developed an in-house finite element analysis code to study the behavior of piezoelectric structures in composites materials.

Thesis title: Finite Element Model of Structures with Piezoelectric Elements.

Masters of Engineering

(Mechanical Engineering)

September 1997 - November 1999

Carleton University, Ottawa, Canada

Research: Numerical modeling of the formation of dendrites during the solidification of tertiary alloys composed of Aluminum, Copper and Silicon. The computer model is based on the finite difference method and concentration differences of the three elements to calculate the morphology of the dendrite.

Thesis title: Three Dimensional Computer Modeling of Dendrite Growth in Tertiary Al-Cu-Si Alloys.

Bachelor of Engineering

(Mechanical Engineering)

September 1991 - November 1995

Carleton University, Ottawa, Canada

Thesis Project: Developed a custom software package to predict austenization time for complete formation of austenite from pearlite, without unnecessary grain growth

Research

A Holistic Approach to Structural Integrity Process (HolSIP)

Dr. Martinez is working on the development of a Holistic Structural Integrity Process, known as HolSIP. This process is physics-based and founded upon the primary idea that all failure mechanisms involved in the degradation of the structure are interconnected and should not be analyzed as merely the sum of individual mechanisms. In reality, many failure mechanisms interact synergistically and are much more complex and challenging to understand, and thus the requirement for a holistic physics based analysis and design approach to structural integrity problems. In order to achieve such a goal, HolSIP combines research fields such as: Health Usage Monitoring (HUMS), Structural Health Monitoring (SHM), Adaptive Structures, Machine Learning Algorithms, initial and current structural conditions, Flight Load and Condition Monitoring. As part of his research, Dr. Martinez, focuses on advancements in the field of SHM, Load Monitoring and fatigue of metallic and composites structures.

Electromechanical Test Frame

5000 lbf (22kN) Eletromechanical test frame.

11200 lbf (50kN) Electromechanical test frame.

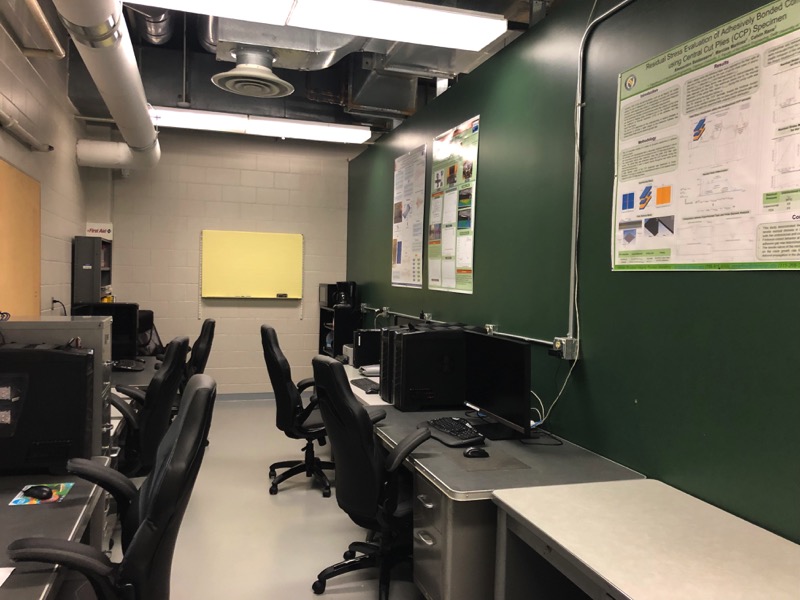

Computing Facilities

Six dedicated Windows 10 workstations, with dual Intel Xeon E5-2650 v3 Haswell 2.3GHz Processor for a total of 40 concurrent threads on each workstation. 4.5TB of Hard Drive data storage space 128 GB of RAM expandable to 1TB. Tesla K40c NVIDIA GPU Card for computational acceleration.

Access to two dedicated nodes at the ACRES Cluster at Clarkson University (80 dedicated cores).

Experimental Mechanic Techniques

LUNA -Rayleigh Backscattering Distributed Strain and Temperature Sensing System

National Instruments Strain Gauge, Temperature and Voltage DAQ System (Compact DAQ)

DeweSoft DAQ System.

2D & 3D - Correlated Solutions Digital Image Correlation (4 cameras)

National Instruments - Strain Gauging Equipment (multiple channels and thermocouples)

Extensometer.

FLIR Thermographic Camera.

Software

SolidWorks

ABAQUS, iSIGHT, TOSCA, FE-SAFE

Matlab

GID Pre/Post Processor

Visual Development Studio

ANSYS

OnScale

AFGROW (Fatigue Crack Growth Program)

SHM Equipment / NDI Equipment

Acoustic Emissions System: One AMSY-6 Main Chassis, with 6 slots for ASIP-2 for up to 12 AE Channels.

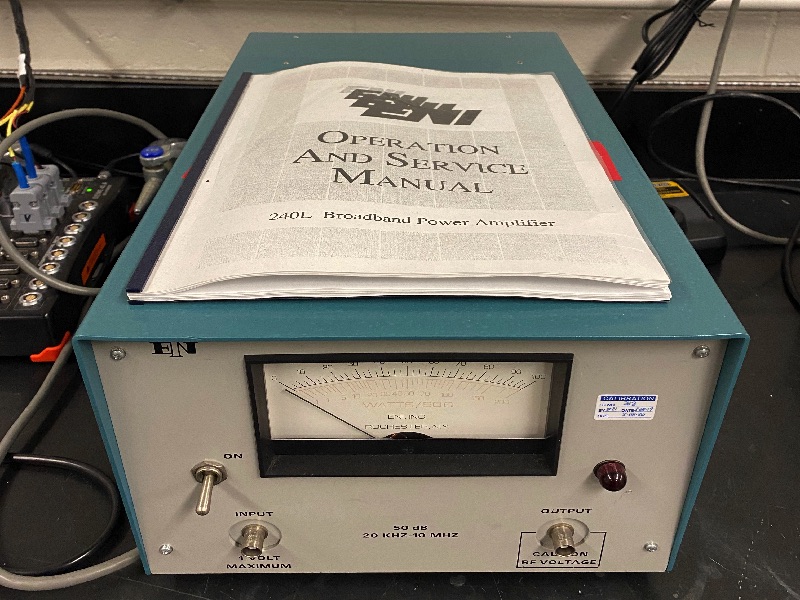

High power voltage amplifier

Sonatest, Phased Array System (thorugh the Center for Advance Material Processing).

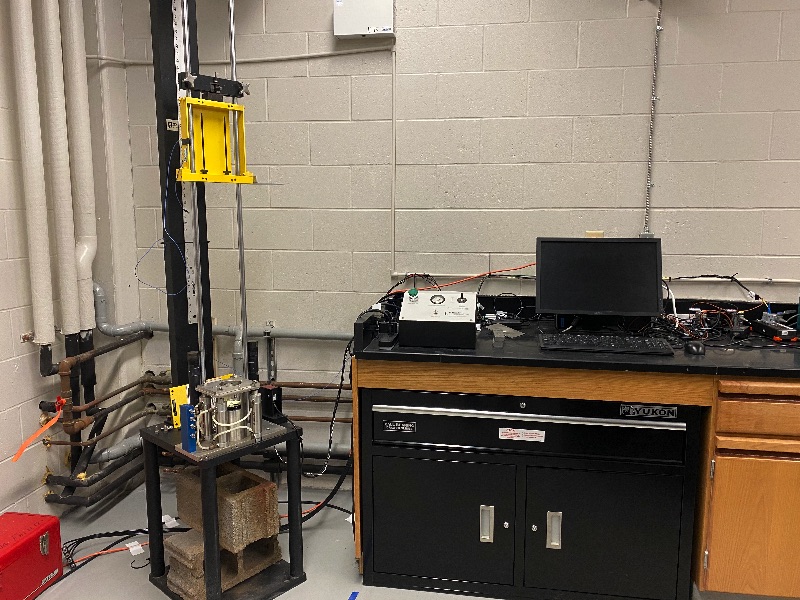

Drop Tower

Instrumented Drop Tower

Meet our Research Team

A skilled group of multi-disciplinary Individuals

Todd Mull

Ph.D. Research: NDE of Composite Structures

Location: Clarkson University (Potsdam, NY, USA)

Cornelis de Mooij

Ph.D. Research: Load Monitoring of Aerospace Structuring through the use of inverse Finite Element Methods

Location: Delft University of Technology (Netherlands)

John Erdman

M.Sc. Research: Composite Non-Linearity

Location: Clarkson University, Potsdam, NY

John Onafowokan

M.S. Research: Cold Hole Expansion Process

Location: Clarkson University, Potsdam, NY.

Dor Jacobi

M.Sc. Research:Evolution of Strain in Adhesive Bonded Joints

Location: Clarkson University, Potsdam, NY

Evan Miller

M.S. Research: Machine Learning for a Production Process

Location: Clarkson University, Potsdam, NY

Past Graduate Students

Mr. Tyler Hill, (September 2025), M.S., - Clarkson University

Mr. Andrew Lally (June 2024), M.S., - Clarkson University

Miss Jannatul Ferdaussi, M.S., (Dec. 2023) - Clarkson University

Mr. Minhaz Morshed, M.S., (August 2023) - Clarkson University

Mr. Todd Mull (July 2023), M.S., - Clarkson University

Miss Juliana Garcia, M.S., (July 2023) - Clarkson University

Mr. Johsua Alamo, M.S. (May 2023) - Clarkson University

Dr. Alessandro Baldassarre, Ph.D. (December 2021) - Clarkson University

Dr. Christian Garcia Ph.D. (May 2015) - Carleton University

Dr. Shashank Pant, Ph.D. (June 2014) - Carleton University

Mr. Joshua Alamo, M.S. (April 2023) - Clarkson University

Mr. David Mackey, M.S. (July 2021) - Clarkson University

Mr. Brian Pfeil, M.S. (July 2020) - Clarkson University

Mr. Prem Annand, M.S. (May 2017) - Carleton University

Mr. Jacob Miller, M.S. (May 2017) - Clarkson University

Mr. Ewould Aaij, M.S. (April 2016) - TU Delft

Mr. Alexandru Vargalui, M.S. (May 2015)- TU Delft

Mr. Rutger Stottelaar, M.S. (January 2015) - TU Delft

Mr. Maurice Boon, M.S. (July 2014) - TU Delft

Miss Patricia Martinez, M.S. (March 2014) - TU Delft

Mr. Tom Lotz, M.S. (January 2014) - TU Delft

Mr. Darun Barazanchy, M.S. (August 2013) - TU Delft

Mr. Ghazi Alsoruji, M.S. (May 2013) - Carleton University

Mr. Fady Habib, M.S. (December 2011) - Carleton University

Mr. Robert Kernaghan, M.S. (December 2011) - Carleton University

Mr. Terrence Cheung, M.Eng. (December 2011) - Carleton University

Dr. Martinez has co-supervised over 10 graduate students at other institutions who have spent time at the HolSIP lab at Clarkson University.

Open House Video

Video created by Prof. Martinez showcasing Clarkson University and the Department of Mechanical and Aerospace Engineering

AidFab - Facilities at Clarkson University

Description of our new 3D printing lab.

Clarkson Composite Lab

Video describing AE / ME 457 Course run by Prof. Marcias Martinez